Lead your project to a more improved value with respect to the initial cost, operating cost, and returns on investment. With quality checks at every level of detail, 3DESIGNWORX delivers MEP/FP clash detection solutions within a stipulated time-frame conveniently.

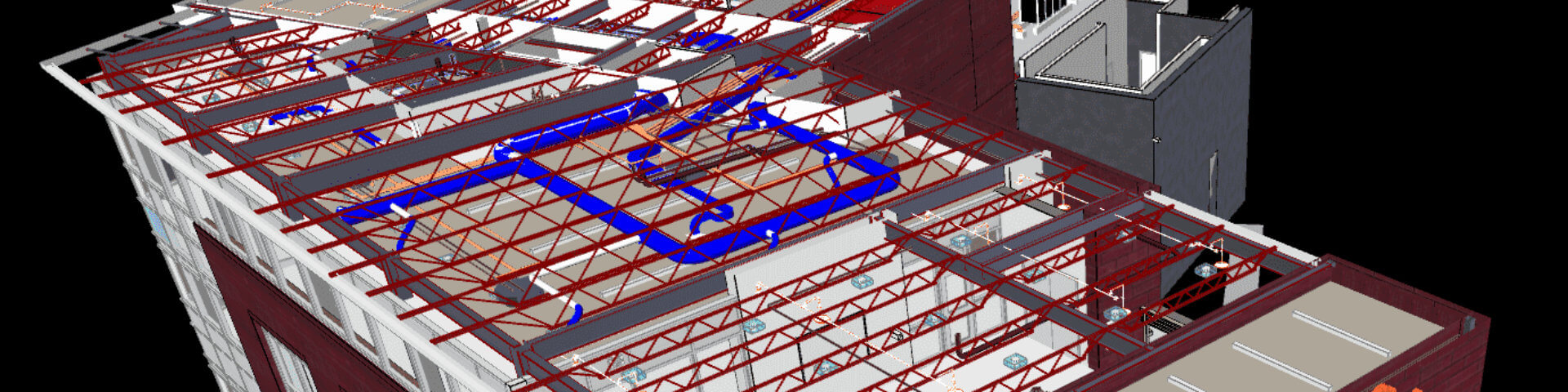

Perform your Revit model set-up, along with modeling and coordinating all MEP/FP Systems. The final product will result in an as-built 3D model and 2D coordination for your field teams.

MEP/FP Clash Detection: What Is It All About?

Ever wondered why building projects run into costly delays or rework? More often than not, the answer lies in the hidden conflicts between systems—especially the mechanical, electrical, plumbing, and fire protection elements. That’s where MEP/FP clash detection steps in.

MEP/FP clash detection is a process that identifies spatial and functional conflicts in your construction model before any real-world work begins. It ensures that pipes don’t intersect with ducts, cable trays don’t cross beams, and fire protection systems don’t interfere with structural elements. Using intelligent tools like Autodesk Revit and Navisworks, this service helps catch design errors early—long before construction crews hit the site.

As part of our broader VDC services in Charlotte, North Carolina, this process plays a key role in improving coordination between disciplines and enhancing constructability. It ensures that all systems are accurately modeled and properly integrated, reducing miscommunication between design and field teams.

At 3DESIGNWORX, we approach MEP/FP clash detection as a proactive strategy—not just a fix. Whether you’re dealing with tight ceiling spaces, complicated risers, or complex utility layouts, our goal is to spot and resolve coordination problems before they cost you time or money.

MEP/FP Clash Detection: What to Expect?

When you work with a clash detection team, here’s what you can typically expect throughout the process:

- Comprehensive Revit Model Set-Up

We begin with setting up your Revit models based on your project’s architectural and structural files. This ensures all design disciplines are working within a coordinated environment.

- Detailed MEP/FP System Modeling

We create precise 3D models of mechanical, electrical, plumbing, and fire protection systems. Each element is modeled with attention to real-world installation constraints and manufacturer specifications.

- Advanced Clash Detection & Resolution

Using clash detection software, we identify hard and soft clashes between systems and structures. Each conflict is reviewed and addressed collaboratively to avoid change orders down the road.

- Constructability Review and Reporting

We don’t just point out problems—we help solve them. Our team prepares detailed clash reports, suggests reroutes or layout changes, and ensures compliance with building codes and field feasibility.

- Coordinated As-Built 3D Model and 2D Drawings

Finally, the result is a fully coordinated, clash-free as-built model. We also generate 2D coordination drawings that can guide field teams during installation, making on-site execution much smoother.

Why Does MEP/FP Clash Detection Matter?

Clashes between systems aren’t always obvious during early design phases. Without clash detection, teams often discover issues during installation—which leads to costly rework, missed deadlines, and frustrated stakeholders. By investing in clash detection early on, you’re investing in the long-term efficiency and reliability of your project. Whether you’re working on commercial, residential, or industrial buildings, this service ensures fewer surprises and more predictability.

Frequently Asked Questions (FAQs)

What is MEP/FP clash detection in construction?

MEP/FP clash detection identifies conflicts between mechanical, electrical, plumbing, and fire protection systems within a building model before construction begins.

Why is clash detection important in BIM?

Clash detection helps prevent costly on-site errors by catching design conflicts in the digital model. It improves coordination among trades and reduces change orders.

How does clash detection work in Revit and Navisworks?

Revit is used to create detailed models of all systems, while Navisworks runs clash detection by comparing all model elements for interference or spatial overlap.

When should I perform MEP/FP clash detection in a project?

Clash detection is most effective during the design development or preconstruction phase before materials are ordered and fieldwork begins.

What types of clashes can be detected?

Clash detection tools can identify hard clashes (physical overlaps), soft clashes (violations of clearance or buffer zones), and workflow clashes (scheduling conflicts).

Is clash detection only used in large-scale projects?

No. Even small or mid-sized projects benefit from clash detection, especially when there are tight spaces, multiple systems, or complex routing requirements.

What happens after a clash is found?

Once a clash is detected, the design team reviews it and adjusts the model accordingly. This may involve rerouting a system, resizing components, or modifying layouts.

Let’s Build the Future Together

Ready to bring your project to life with precision and clarity? Contact us today and see how our BIM expertise can streamline your entire construction process.